The Tamesis Trust

First report on the examination of Cygnet

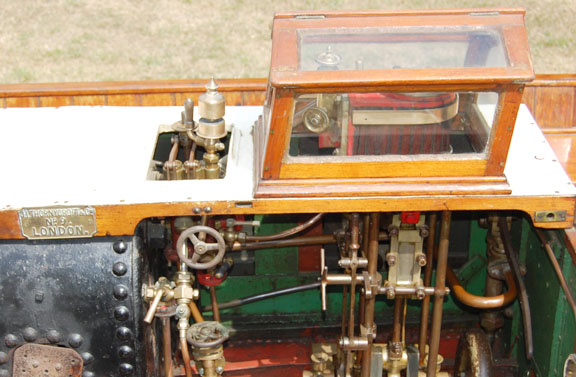

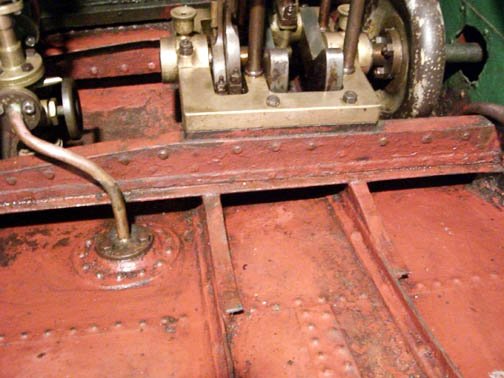

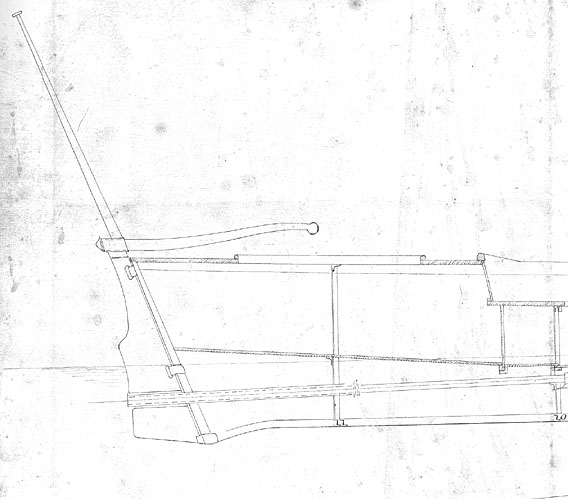

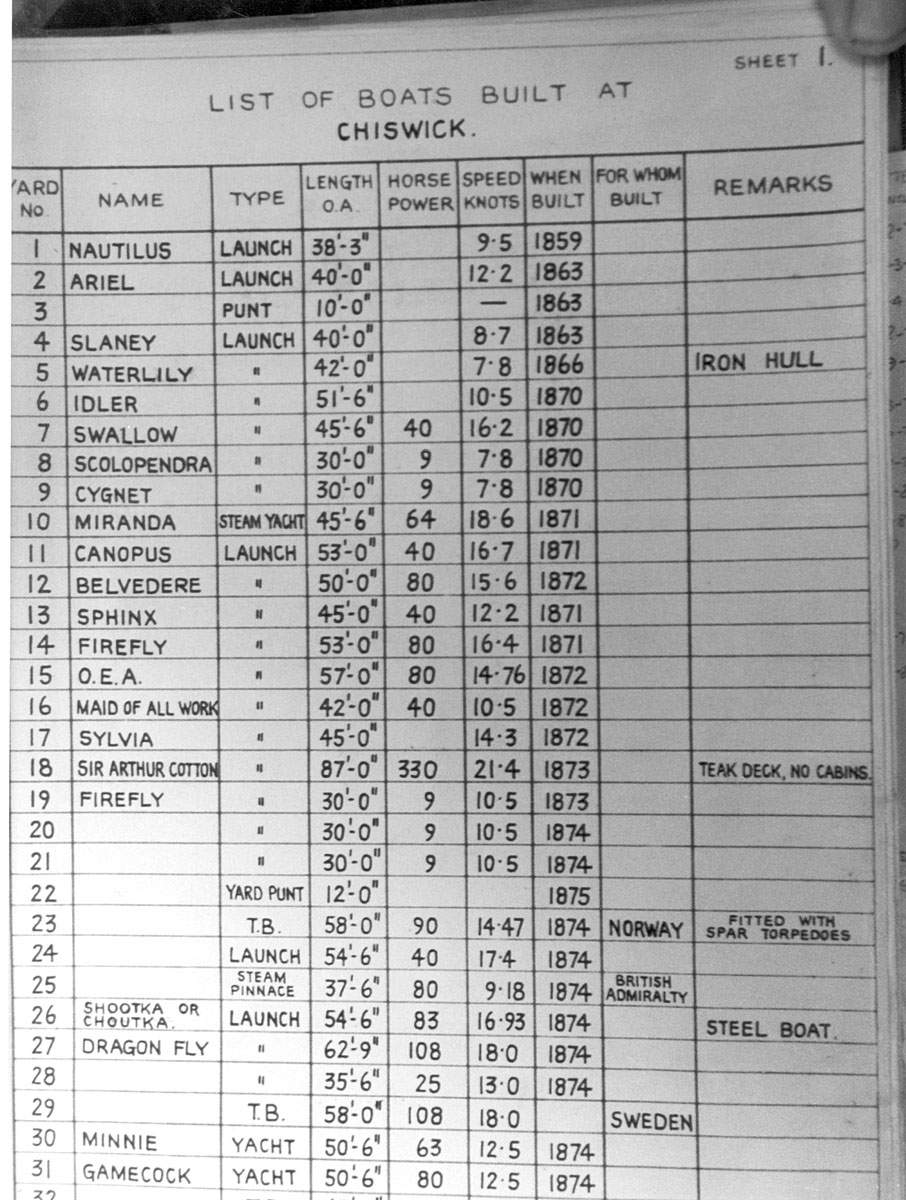

Cygnet is a 29ft long steel hull steam launch built by J.I. Thornycroft in 1870

|

|

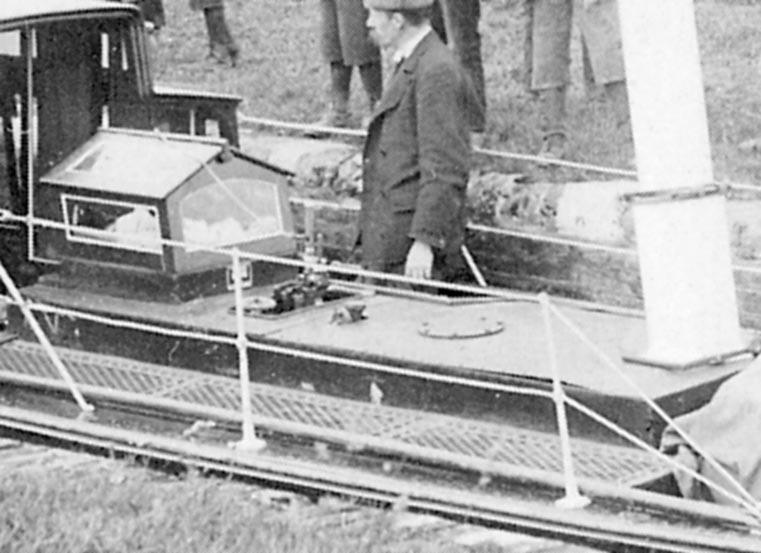

| Cygnet in steam at Steamboat Rally based at Datchet in 1970 | Thornycroft's list of boats, Cygnet is No.9 |

|

Work has started to assess the condition and prepare Cygnet ready for public display. The examination has revealed many details of the construction techniques used by Thornycroft during the early years of this important shipbuilder's business |